EDACafe Editorial Roberto Frazzoli

Roberto Frazzoli is a contributing editor to EDACafe. His interests as a technology journalist focus on the semiconductor ecosystem in all its aspects. Roberto started covering electronics in 1987. His weekly contribution to EDACafe started in early 2019. Siemens enters the IC power integrity analysis market with a solution for analog, digital and mixed-signal designs of any sizeSeptember 28th, 2021 by Roberto Frazzoli

Called mPower, the new software fills an important gap in the EDA market, says Siemens’ Joe Davis Smaller process geometries make electromigration (EM) and voltage drop (IR) analysis more important than ever for new chip designs, as interconnects and material layers get thinner and thinner. At the same time, smaller geometries mean skyrocketing transistor counts, making detailed EM/IR analysis of a full design a daunting task. On top of that, the growth of sensor-based applications leads to larger analog blocks, where the techniques used in digital blocks to simplify EM/IR analysis are not applicable. Is the EDA industry keeping pace with the ever-harder requirements of power integrity analysis? According to Siemens, until yesterday the answer was no – and this resulted in some critical pain points. “The largest, most complex analog systems are often sent to manufacturing without a detailed EM/IR analysis; simplifications, subsetting the design, less accurate simulators and other ad hoc methods are used as approximations; lack of detailed EM and IR analysis for large-scale analog circuits puts the whole system at risk,” Siemens maintains in a document on this topic. Identifying those pain points as a market opportunity, Siemens is now introducing its new mPower power integrity software for analog, digital and mixed-signal IC designs. Let’s take a closer look at mPower with the help of Joe Davis – Senior Director at Calibre Interfaces, EM/IR Product Management at Siemens – who recently gave a video interview on this topic to Sanjay Gangal from EDACafe.

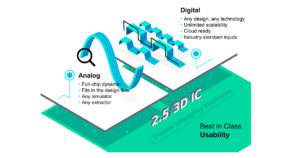

Power integrity analysis, a critical step Davis started out by underlining the importance of power integrity analysis to ensure that the design of an advanced chip is actually ready for manufacturing. “Power integrity is an integral part of the design and verification process,” he said, “where the design teams have to take a detailed look at how power is actually being delivered during the operation of the circuit as it’s implemented, as well as the performance and reliability of the implemented die. As you go through the design process, there are lots of models and approximations that are applied. When you get down to the final design that you’re going to send to manufacturing, you have to ensure that all those pesky parasitics and realities that come from the implementation itself still enable you to reach the performance, the frequencies and power that you’re looking for, still within the target box that you’ve set for your specifications. This is a real critical check to test whether or not your chip is ready to go to market.” Ultimately you got to analyze the whole die,” he added, “whether it’s a transistor level or a gate level, to get that full analysis: are you delivering the current where you need it to, with sufficient voltage to get the performance that you really need, without exceeding electromigration parameters, so that you don’t have reliability problems? You got to do all of this, at this tremendous scale of billions and trillions of polygons.” Filling a gap in the current EDA offering Siemens recognizes that mPower does have some direct competitor – namely, Cadence Voltus and Voltus Fi, and Ansys RedHawk SC and Ansys Totem. However, according to Davis, mPower’s features make it a unique solution. “We are always talking with customers about what are the challenges that they face,” he pointed out. “And one of the things that we have learned is that while there are solutions in place in the market for large digital circuits and for small analog circuits, there’s really a gap where customers have a problem when their analog circuits get larger than a certain size. There are not good solutions in place, and so there’s this hole where you don’t have a tool in the market to do the analysis that the design teams really need to get high confidence for doing tape-outs. We have some technology that we had acquired that we felt could address this solution, both in the digital and in the analog domain, so that we could bring in a new offering that solves both the existing problems and the emergent problems that our customers are seeing become more and more urgent. As customers have larger analog circuits – whether they are sensors or amplifiers, memories, analog subsystems – there has never been a solution in the market that enabled you to do single-run dynamic, EM/IR analysis. That’s really where we differentiate. We also have the capability, with the same tool, to analyze the world’s largest digital chips – so here we have a single solution that we can offer to a customer who has both analog and digital across the scale and across the domains.” Benefits for the engineers designing large analog blocks Although the scope of mPower includes digital designs, Siemens expects its new solution to make a difference mostly for analog designers. “The ones who are going to benefit the most are the ones who have analog circuits that exceed a million or more transistors in their analog circuit or sensor,” Davis said. “These are the ones who are pushing or passing the limits of what their simulators can do to enable dynamic analysis for EM/IR. Spice simulators are always getting faster with more capacity, but engineers are pretty good at designing bigger and more complex circuits that always exceed the capacity of available EDA tools, so those are the customers who will get the most value. And even more than that,” he added, “those customers who have these large analog circuits and large digital circuits at the same time. With the IoT trends in the market, there are more and more companies designing in this space: big digital, with big analog and sensors, all in a single die.” Peculiarity of the analog domain Davis also elaborated on the reasons why power integrity analysis in the analog domain is more challenging than in the digital domain. “Analog is transistor level, digital is gate level,” he said. “Digital folks have spent the last twenty years perfecting the art of abstraction and scale. Today’s designs are in the fifteen, twenty billion gate [range], and so there’s a very strict hierarchy that digital designers employ to do designs across that kind of scale. That gives you methodologies in the design environment and in the analysis environment that enable you to scale that way. On the analog side, Spice is king. It’s all about transistors and continuous waveforms and so forth, and while there is hierarchy in the design, there’s not as much ability to scale hierarchically the types of design analysis across the hierarchy. Because of that, analog designers and analog design flows are not well suited to the same sorts of abstraction that the digital designers have been using for many, many years. And so, in order to provide a scalable verification solution, we have to fit within the actual Spice and analog design flow in a way that those designers can actually use it in their design flow. We can’t tell them, ‘Hey, Mr. Analog designer, go pretend that you’re a digital designer for a little while.’ They have some very choice words for you, if you tell them that,” Davis joked. Early adopters’ reactions: MaxLinear, Esperanto, OnSemi The mPower announcement is accompanied by some customer testimonials, since “mPower has actually been in production for quite a while now,” as Davis explained. “We have been working with customers across a variety of technologies, and some of the customers who have come forth for this announcement very graciously shared their experiences with the market,” he commented. “Some of the customers were like MaxLinear, who we’ve worked with at five nanometer analog design. We helped them with a scalable, high capacity dynamic analysis that enabled them to do design on large analog blocks that they’ve never been able to do before. We also worked with companies such as Esperanto, who has a very large digital AI chip; we’re working with them to perform analysis on their network that they were not able to do with a competing tool, and so we provided that scalability in the digital space. And then in mixed-signal you’ve got OnSemi: their chips are half analog, half digital, married to a sensor array. So they got to have it all: big digital, big analog, all at the same time from a single vendor in a single flow.” Siemens’ expectations As a new challenger in the EM/IR power integrity sign-off space, mPower will have to convince customers to switch from previous solutions. Will it succeed in doing so? “There’s no clear yes or no answer, like there is with DRC or LVS,” Davis conceded. “EM/IR and power integrity requires a lot of methodology and so customers have to be very cautious in making a decision to switch for sign-off because they have to get comfortable. For those customers who have large analog circuits, there will be little hesitation, we believe: there’s a huge value for mPower. For those customers who spend the rest of the market on the pure digital side and small analog, we’ve seen a great interest from the market for a third option. And the leverage of working across the electrophysical sign-off suite within Siemens with PERC, with HyperLynx and PowerPro – as well as the other suite of Siemens tool – provides a great advantage for our customers. It provides a great value in putting together a whole flow for electrophysical sign-off.” mPower and the other Siemens power integrity products This latter comment brings us to the overall Siemens product offering in the power integrity space, and how mPower fits into it. Siemens describes mPower as the completion of its overall electro-physical signoff suite addressing power, performance, and reliability analysis. Other offerings in this suite include Calibre PERC reliability software, PowerPro software, HyperLynx software, and the Analog FastSPICE platforms. With the addition of mPower, designers can now use an all-Siemens power integrity design flow, the company maintains. Commenting on single products, Davis explained that HyperLynx comes into play on the board and package side, where designers deal with both power integrity and signal integrity together. He then moved to PERC, explaining that it addresses the market segment for electrical overstress and ESD. “It’s also a very generic tool that can be applied to many different types of reliability challenges,” he said, “where you’re looking at doing topological filtering of the circuit to identify polygons in the layout and take a very close look at those. It’s a generic tool that addresses a lot of different things, but has been lately focused on ESD and EOS. mPower is a very complementary solution to PERC, an out-of-the-box solution for power, IR drop, electro-migration for analog and digital,” Davis continued. “We are very focused on this particular market segment, because it’s a very clear market need and activity in the design flow. ESD and EOS and all the other reliability things that PERC does scale far beyond that market area. We are collaborating with the PERC team so that in the future we will be bringing out solutions where one tool feeds the other, but right now those solutions are in the idea stage.” Ease of use As Davis briefly mentioned when talking about the need to fit within the actual Spice and analog design flow, a key mPower feature claimed by Siemens is ease of use. According to a Siemens document, “except for the very largest companies, EM/IR sign-off is a job that most design engineers do once or twice a year. This means that every user is a novice user, to some extent. In larger companies, CAD teams build wrappers around the EDA tools to make them usable by the design teams, but this isn’t possible for the vast majority of companies. The result is that designers spend a lot of time just getting the tool to run, or figuring out what the results mean, and EoU is a big deal at that time. It is important that the sign-off tool fits well into the design flow and minimizes any special inputs or work.” Siemens maintains that “mPower leverages standard file formats and interfaces to make it easier for customers to use and deploy it within a heterogeneous design flow – whereas other tools have striven for vendor-specific formats and vendor-specific design flows.” As Siemens points out, mPower can work with any parasitic extractor and any simulator that can create an FSDB waveform database. mPower has some additional capabilities if Calibre PEX or Analog FastSPICE (AFS) are used in the flow, but these are not required. Next steps A new product line, mPower Power Integrity is comprised of two products for gate-level and transistor-level EM/IR sign-off. The solution is designed to scale for both analog and digital designs: Siemens claims to have customers with designs exceeding 550mm2 at advanced nodes. In addition to 2D designs, mPower can also be applied to 2.5/3D IC implementations at any scale. The solution is ready for process technologies down to 5nm, “and we’re already working on the next technologies, of course,” Davis pointed out. As for the current version of the product, “we’ve already finished qualifications at a number of technologies and foundries that will be coming out in press releases in coming weeks,” Davis concluded. More information about mPower can be found in this fact sheet. An mPower introductory white paper can be accessed from this page. A white paper on using mPower in UPMEM PIM-DRAM design can be accessed from this page. Categories: EDACafe Editorial, Video Interview |

|

|

|||||

|

|

|||||

|

|||||