Siemens EDA Lee Wang

Lee is the principal product manager for the Calibre 3DThermal product. Chip-level thermal analysis solves a main barrier to 3DICsSeptember 12th, 2024 by Lee Wang

As the semiconductor industry adds more functionality into smaller footprints, we are pushing the boundaries of traditional two-dimensional integrated circuit (2DIC) designs. The next phase in the growth of performance and functionality is building three-dimensional integrated circuits (3DICs). However, this new dimension introduces a host of challenges, the most significant of which is managing heat dissipation. The allure and pitfalls of 3DICs The advantages of stacked dies interconnected using vertical interconnect accesses (vias), to create a single, compact package include:

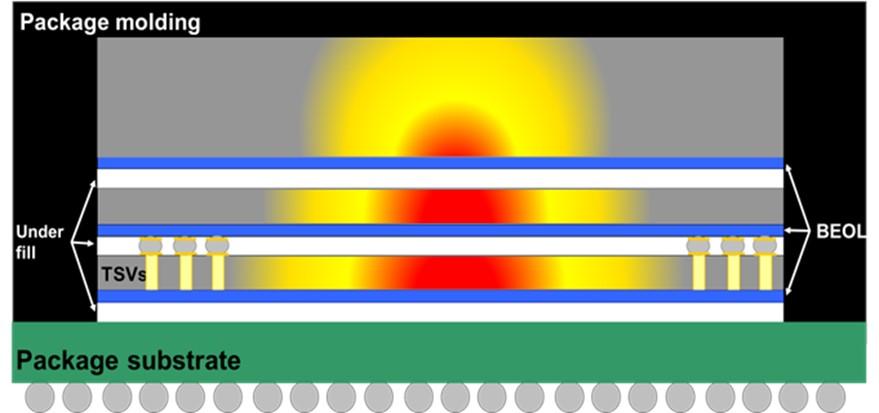

To realize these benefits, designers first need to clear some key hurdles, including the significant challenge of managing heat dissipation (figure 1). Because 3DIC architectures are so compact, heat generated by the densely packed components can cause hot spots that affect performance and reliability.  Figure 1. Illustration of a 3DIC with heat dissipation.

So, robust thermal management is essential as the designers continue to develop 3DICs devices. Traditionally, thermal analysis has been performed at the package and system levels, often as a separate process from IC design. However, this approach is no longer sufficient for 3DICs. Designers need to perform thermal analysis at the die level, starting at the early chip/package design phase in order to identify and mitigate potential thermal issues before they become critical problems. Early-stage thermal analysis helps to:

Solutions for die-level thermal analysis Solutions for accurate thermal analysis in the 3D assembly (die-to-die and die-to-package) required design automation software to create new tools and flows. The new flows enable comprehensive thermal analysis from the early stages of design through to final signoff, allowing for continuous thermal management and optimization. Some key features of a thermal analysis solution for 3DICs include:

Example of an integrated thermal analysis solution One new tool in the market embeds a customized 3D solver from a popular package-level thermal tool within a proven IC design platform. This combination lets designers perform accurate chip and package-level static or dynamic thermal analysis of the full 3DIC assembly. It also allows for early and continuous thermal assessment from initial feasibility analysis to design signoff and is integrated with other 3D design tools and flows from IC to package to system levels. It supports all 3D integration technologies, including chiplets on package, interposers with through-silicon vias (TSVs) and direct bonding techniques. Thermal analysis, debug and verification throughout the design flow Designers need to track, fix, and verify thermal issues throughout the design flow, including:

Usability Many 3DIC designers will not have the experience of a thermal engineer, so thermal analysis at the die level must be user-friendly. Examples of advanced automation to help 3DIC designers include:

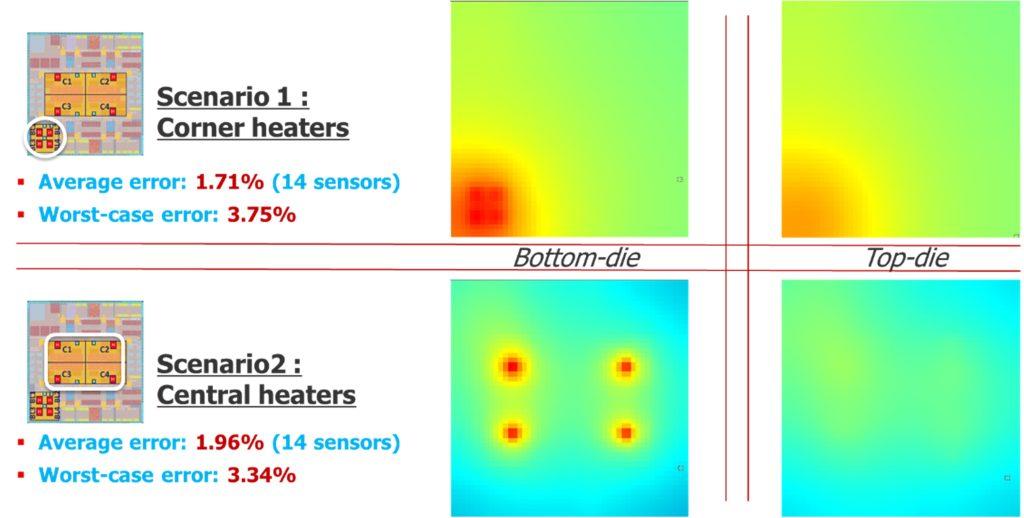

Examples of 3DIC thermal analysis Some real-world applications demonstrate the practical benefits of integrated thermal analysis solutions. The research organization, CEA, used the 3D thermal analysis tool from Siemens EDA to study the thermal performance of their 3DNoC demonstrator. The thermal model they developed showed excellent correlation between simulation and measured data with a worst-case difference of just 3.75% and average difference within 2% (figure 2).  Figure 2. Correlation of simulation versus measured results. CEA also use the Calibre 3DThermal tool to perform chip-package thermal co-design on a complex design composed of 16 chiplets on an active interposer. During early design exploration, they performed thermal-aware 3D partitioning and optimized the TIM layers, copper lid, and heatsink design. For design tapeout, they performed thermal-aware signoff analysis, which accounted for the 150K fine-grained 3D structures, such as TSVs and µ-bumps, revealing important anisotropic thermal properties of the die-to-die layers. Detailed and accurate power maps captured the thermal impact of heterogeneous hotspots in multiple power application scenarios. Conclusion 3DICs are a significant leap forward for creating devices with unprecedented levels of performance and functionality. For 3DICs to become a commercial success, the thermal challenges associated with these designs need robust, integrated thermal analysis and management solutions. Designers now have the tools to perform accurate and fast thermal analysis throughout the design flow from early analysis through to design tapeout. We will see rapid adoption of these advanced thermal analysis tools that will help realize the full potential of 3DIC technology. 3D thermal tools not only help designers push the boundaries of what is possible but also ensure that these cutting-edge technologies are reliable, efficient, and ready for the challenges of tomorrow. Category: Siemens |

|

|

|||||

|

|

|||||

|

|||||