EDACafe Editorial Roberto Frazzoli

Roberto Frazzoli is a contributing editor to EDACafe. His interests as a technology journalist focus on the semiconductor ecosystem in all its aspects. Roberto started covering electronics in 1987. His weekly contribution to EDACafe started in early 2019. Turnkey ASIC outsourcing – Presto Engineering’s proposal to Original Device ManufacturersJuly 22nd, 2022 by Roberto Frazzoli

According to the European company specializing in semiconductor design and services, it is now possible to bring an ASIC to market for less than $5 million dollars in upfront investment – and customers lacking semiconductor expertise can lower the risks by outsourcing to Presto the entire ASIC procurement process, from design to delivery It’s a two-speed world: on the one hand, applications such as smartphones or artificial intelligence accelerators keep pushing the semiconductor industry towards Angstrom-scale process nodes and hundreds of billions transistor counts; on the other hand, many end products in a variety of markets – from industrial to medical and more – are still relying on an electronic box containing a PCB with a number of low-integration ICs and discrete components. Replacing the old-style box with an ASIC would clearly provide multiple benefits to the end product, but manufacturers lacking a semiconductor expertise are concerned by the risks of a complex production process. Targeting this largely untapped market, a France-headquartered company called Presto Engineering is addressing European and American manufacturers with a two-pronged message: ASICs are now cheaper and easier to make than ever before, and risks can be reduced by outsourcing the entire ASIC procurement process – from design to delivery – to Presto. Michel Villemain, CEO of Presto Engineering, described his company’s offering in the video interview he recently gave to EDACafe’s Sanjay Gangal; in this article we will add a few details, as well as the answers he provided to some additional questions.

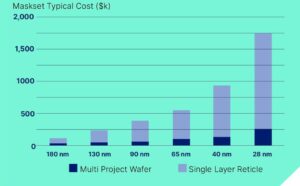

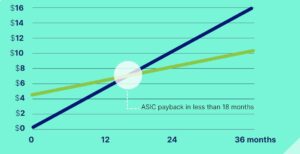

Leveraging the lower cost of mature process nodes According to Presto, the key to making ASICs affordable is taking advantage of mature process nodes, less expensive than the latest ones but still perfectly suited to many applications in industrial, medical, automotive and communication end products. As the company explained in a white paper, with production migrating to the newer lines, older ‘legacy’ fabs are left idle or underused. This surplus capacity has led to dramatic reductions in the cost of ASIC solutions relative to the cost of advanced node products. Non-recurring engineering costs – such as chip design and photomasks – are also much lower for legacy nodes.  The cost of a mask set for different process nodes. Source: Presto Engineering’s white paper “Can a Custom ASIC Be a Gamechanger for Your Next Product?” “Semiconductor is more and more ‘tagged’ to headlines related to smartphones and advanced processes – all pointing to billions (units and dollars). Many applications in our targeted markets, especially industrial and medical, can benefit from mainstream ASICs, which use legacy technology at a much lower cost than an Apple application processor,” Villemain pointed out. “Additionally, many of those replace an electronics box – with standard components – that cost more than ten times an ASIC; therefore, the payback of an ASIC does not require tens of millions of units – sometimes no more than a few hundreds of thousands,” he added.  “This example compares a discrete solution with negligible initial investment and $10 unit cost at a volume of 500,000 units per year with an ASIC solution that has an upfront cost of $4M and a unit cost of $4 at the same volume. With a cost differential $6 per unit saving $3M per year, the initial $4M investment will be paid back in 16 months.” (Source: Presto Engineering’s white paper “Can a Custom ASIC Be a Gamechanger for Your Next Product?”) ASIC design and procurement: a difficult and risky process for most end-product manufacturers But device cost is not the only factor weighed by end-product manufacturers when it comes to deciding to develop an ASIC. As Presto explains in the above-mentioned white paper, an additional hurdle is the risk associated with the complexity of ASIC development and procurement – a process encompassing multiple steps: design, layout, test development, wafer supply, wafer fabrication, production testing, package development and assembly, components supply, logistics, and supply chain management. Additional requirements include established relationships with foundries and other suppliers in a globalized ecosystem. Large companies, like automotive manufacturers, might assemble whole organizations with the sole task of managing ASIC production, but this move may prove too expensive and risky for smaller manufacturers whose core business has nothing to do with semiconductors. According to Presto, there is now a demand for companies that can manage the entire ASIC procurement process from initial design to final delivery. Over the years, Presto Engineering has built such an offering through investments – 50 million euros in equipment value, manufacturing test assets, and a device packaging pilot line – and in part through acquisitions: in 2020 the French company acquired Denmark-based Delta Microelectronics, a specialist with 35-year experience in designing and producing ASICs. Let’s now take a quick look at the Presto Engineering’s service offering. Presto Engineering’s ASIC design services: IP portfolio and toolboxes The ASIC design process performed by Presto’s engineers starts with a feasibility analysis of the customer’s project. ASIC design then takes place leveraging Presto’s silicon IP portfolio, which encompasses “foundation IPs” and “platform functional blocks”. Foundation IPs include circuit blocks such as – for example – temperature sensors, optical array sensors, as well as digital controllers, LVDS IOs etc. Platform functional blocks include, for example, high dynamic optical front-end, ultra-low power motion ISP and MCU, RFID/NFC/UHF/ISM connectivity, energy management & harvesting. Presto Engineering’s IP portfolio – as well as its design practice – comes from the above-mentioned acquisition of Delta Microelectronics. Validation of ASIC project ideas involving certain specific functions – namely, NFC and low power image processing – can also take advantage of two “toolboxes” prepared by Presto. Package design Services offered by Presto for ASIC packaging cover package selection, design, qualification, and production. The range of available package solutions includes lead frames and laminate-based, BGA to surface mount packages, smart card modules, and in-lays and flex circuits, as well as wafer-level packaging and bumping options for WLCSP soldering. The company can tap into a database of 850 already-validated packages. Test services, qualification, failure analysis As for ASIC test, Presto takes care of test plan generation, hardware and software development, preparation of custom ATE set-ups, etc. Besides digital ICs, memories and mixed-signal ICs, the range of testable components includes image sensors, MEMS, RF devices and LiDARs. Presto claims a unique expertise in RF test applications, with low cost-of-test solutions for automotive radar, and transceivers integrating beamforming, and the ability of testing even high bandwidth devices up to E-Band, as well as millimeter wave RF at wafer-level. Qualification services offered include high/low temperature operating life (HTOL/LTOL – device qualification) and highly accelerated stress test (HAST – package qualification). The offering includes failure analysis capabilities. “We are very strong in qualification. And the process of qualifying a part from a reliability standpoint, especially for automotive, is one of the most stringent requirements,” Villemain commented. ASIC production and supply chain management Moving to semiconductor production, Presto Engineering takes care of supplier management, planning, purchasing, and logistics. This latter function also leverages a Hong Kong-based warehouse. The company operates five test floors, including two in Asia (in Bangkok, Thailand and in Kaohsiung, Taiwan) where the production is supervised on-site by Presto’s resident personnel. Company assets include ATE capacity, as well as lines of wafer backend processing (back lapping, back grinding/thinning and dicing) and finishing (visual inspection, packing, tape & rill). Most of the company’s floors are secured (EAL 6 certified). Presto Engineering can use different foundries depending on the project’s requirement. “We don’t necessarily have ‘target’ foundries,” Villemain pointed out. “We deal with most of the top ten foundries in the industry. When we select a foundry for a project – a step that comes with our feasibility study and results in a very thorough analysis of the available field – our criteria include IP, price and, more and more, security of supply,” he said. For the post-foundry manufacturing steps, Presto partners with OSATs and EMS that can process lots under the same roof, from probe test to wafer backend, assembly, final test, and finishing. As Villemain said in the video interview, the company is combating the current capacity crunch with initiatives such as recommending double sourcing, qualifying alternative materials, tightening its relationships with suppliers. Proprietary platforms and processes for supply chain management and design quality According to Villemain, a key competitive factor for Presto Engineering is its “Ocean” proprietary web-based platform for supply chain management. “It manages our supply chains completely electronically (business-to-business) which allows full traceability, quite critical for certification-heavy sectors like automotive or medical,” he explained. The Ocean platform allows error-free transmission of production files and instructions, as well as consolidation of the feedbacks. Besides Ocean, specifically for production, Presto Engineering has developed two more proprietary processes: QuDF (ASIC Quality Design Flow) and SQuP (Service Quality and Planning). “Our proprietary processes, QuDF for design and SQuP for post-silicon, allow us more predictability and visibility for our customer,” Villemain maintained, “as well as more efficiency from our teams, since they execute the same process for each project. This quite dramatically improves our ability to reuse (IP, methods, libraries, failure mechanisms, etc.) which is the only real way to de-risk projects that, by essence, have never been done before. Finally – he continued – our processes are governed (and the resulting data managed) by our Ocean platform, which makes them more systematically implemented.” Specializing in industrial, medical, automotive and communication applications Presto Engineering boasts specific expertise in applications involving mixed-signals, radio-frequency, sensors, noisy signal processing at low power, analog, and security requirements. Here are some examples of Presto Engineering’s claimed expertise. In the industrial area: sensor-based ASICs aimed at applications such as IIoT (Industrial Internet of Things) solutions used for smart tracking and data logging, automation, preventive maintenance, production machinery, surveillance, smart buildings etc. In the medical area: applications for diagnostics and proactive medicine, connected solutions of Medical Internet of Thing (MedIoT), in-vitro diagnostics, medical wearable devices, medical imaging. In the automotive and transport area: hybrid, electric and powertrain electronics, ADAS, in-vehicle infotainment and cluster, passive safety and functional reliability. “We have a strong legacy in automotive,” Villemain underlined, “because one of the operations we took over from NXP was actually involved in highly innovative automotive applications.” Fifty new product introductions per year on average Founded in 2006, Presto Engineering is headquartered in Meyreuil, France – with operations in France, Denmark, UK, North America and Asia – and has approximately 150 employees. As Villemain recalled in the video interview, over the past fifteen years the company has enjoyed a steady revenue growth, on average 35% year-on-year. The company grew both organically and through acquisitions, targeted at expanding its service offering up to reaching the current ‘turnkey’ ASIC development offering. Acquisitions included a lab from Cypress in 2007, a lab from NXP in France in 2010, the TPE team from ST Ericsson in 2010, HDMI ETC from NXP in 2013, a French company called Inside Secure in 2015, and the microelectronics business of Delta Microelectronics in 2020. On average, the company completes approximately fifty projects per year, shipping sone fifty million units per year. Some of its ASIC case studies can be found here. As Villemain underlined in the video interview, Presto Engineering places great importance on being an equal opportunity employer; its latest gender equality index score can be found here. Category: Video Interview |

|

|

|||||

|

|

|||||

|

|||||