Over the years, Arteris IP has worked with several aerospace, transportation and automotive partners on design systems for avionics, space image processing and processing for scientific payloads. More recently, complex advanced driver-assistance systems (ADAS) projects at various levels of autonomy have been added to the list. One thing common between all these projects has been the tight coupling between system-level specification and all aspects of software and hardware from multiple suppliers and integrators, along with the very tight demands on safety and reliability. All are governed by standards like DO-254, ISO 26262, ECSS-Q80 and others. A common theme in all these standards is the expectation of being able to trace requirements from the system definition to implementation and verification. If a change is made anywhere which invalidates a requirement in this complex web of suppliers and integrators, that problem should be immediately detectable.

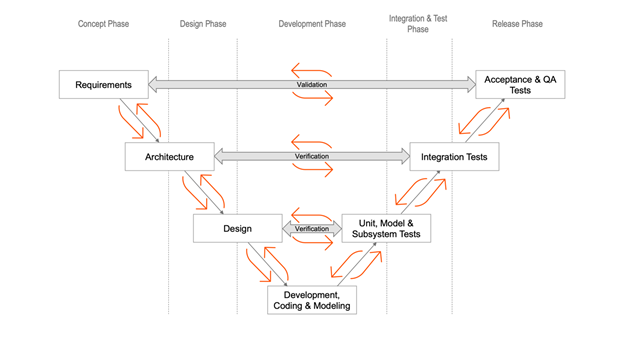

Figure 1: Traceability requires linking artifacts and decisions forwards and backwards in time, and at two different

levels: (1) Along the “V” and (2) Across the “V.”

There Is no Escaping Traceability

Although traceability has always been expected in aircraft and spacecraft design, the scope of safety-critical applications has grown beyond the traditional bounds. ISO 26262 requires that safety requirements in the automotive industry must be traceable. Also, IEC 61508 (general electronic safety) and IEC 60601 (medical electrical equipment) require traceability for functional safety. The bottom line, it is getting much harder to avoid traceability requirements.

(more…)