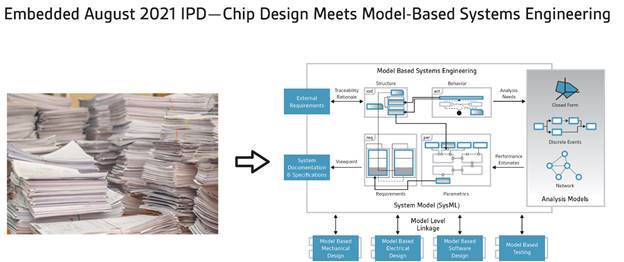

In technology, the only constant is change, sometimes at a dizzying pace. One emerging trend is how product specifications, additions and changes are passed onto system-on-chip (SoC) design teams. Traditionally, this transfer is done by exchanging documents, models (perhaps Simulink) and some form of written use-case descriptions. However, this process is very cumbersome, subjective and error-prone. It is also a very poor method for documenting and tracking revisions required by agile design teams employing best practices. It may not be a problem when building catalog products, but the world has changed. Requirements are now defined much more collaboratively in automotive, aerospace and other domains and enabled by a process called model-based systems engineering (MBSE).

What Is Model-Based Systems Engineering?

Systems engineering is about the total system – an aircraft, spacecraft, airport or seaport, or more recently, a car, truck, and high-speed trains. These systems are architected by teams using many disciplines: mechanical, electrical, software, aerodynamics, thermal, etc. Once each engineering discipline defines the various parameters, each element has a purpose.