Agnisys Automation Review Anupam Bakshi

Anupam Bakshi is Chief Executive Officer (CEO) for Agnisys, Inc., the pioneer and industry leader in Golden Executable Specification Solutions™. From his early days at Gateway Design Automation, through to his time at Cadence, PictureTel, and Avid Technology, he has been passionate about … More » Ensuring Safety: ISO26262 Certification for Semiconductor ExpertsAugust 12th, 2024 by Anupam Bakshi

IntroductionWithin the automotive sector, the safety of electrical and electronic (E/E) systems is mission critical. As many of you likely already know, ISO 26262 is an international standard for functional safety. For our customers designing ASICs for the automotive industry, ISO 26262 serves as the guarantee that, for the lifecycle of the vehicle, adequate safety has been achieved and preserved. With the advent of self-driving cars, safety has taken center stage, and ISO 26262 is the primary industry prescription for developing functionally safe automobiles. This standard covers not just cars, but also trucks, buses, and other types of road vehicles. Understanding ISO 26262ISO 26262 predates autonomous vehicles by years, addressing all aspects of E/E systems in road vehicles. While safety is paramount for self-driving cars, even when a human is at the wheel, safety can be compromised by various types of E/E failures. Therefore, if you’re designing ICs for any part of any electronic subsystem in road vehicles, ISO 26262 is vitally important.

Beyond Automotive: The Importance of Functional SafetyWhen considering safety, there are many other applications where a failure could easily result in serious injuries or loss of life, including implanted medical devices, offensive and defensive weapons, and nuclear power plants. Even misbehavior in an Internet-of-Things (IoT) device – such as your home security system – could have serious consequences for you and your loved ones. In response, the electronics industry has developed a whole catalog of related standards for industrial, railway, avionics, military, machinery, nuclear, and medical applications. Consequently, many designers working on ICs for these applications have already thought seriously about functional safety. The basic idea common to all the safety standards is taking appropriate action in response to a fault in the system to prevent a catastrophic failure. This means designing your chips to detect faults and either correct them or bring the vehicle to a safe condition.

Challenges in Road TravelRoad travel is a notoriously difficult environment for electronic systems. You have extremes in temperature and humidity, noise and vibration, alpha particles that can flip memory bits, chip aging effects, and more. Handling these properly requires safety mechanisms that detect or correct faults due to these challenging conditions. This is an area where you can benefit from the years of experience gleaned in safety-critical design for various applications. Meeting ISO 26262 Requirements with AgnisysAgnisys makes it easy for you to meet the requirements of ISO 26262 and other safety standards. Our IDesignSpec Suite automatically inserts the safety mechanisms you request into its generated register-transfer-level (RTL) designs. These mechanisms are all well-proven by decades of use in a wide range of electronic systems. Agnisys supports the following options:

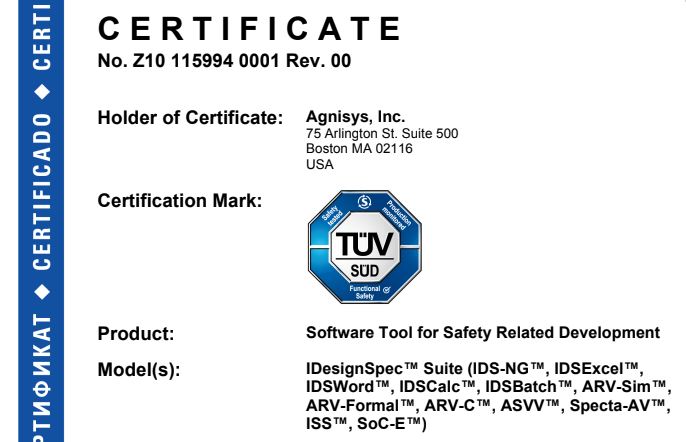

All this support for safety-critical design takes no effort on your part. You simply tell us which safety mechanisms you want in which parts of your chip, and our solution generates them automatically. The safety assessment methods specified in ISO 26262 enable you to gain a quantitative reading on how well your design is protected against faults of all kinds. Your automotive sector customers are certain to be heavily concerned with ISO 26262, and will ask you to show how your chip meets its requirements and whether your design process is compliant to the standard. Ensuring Tool ComplianceSafety standards have a ripple effect: end manufacturers demand compliance from their subsystem developers, who in turn demand it from their chip suppliers, who in turn demand it from their electronic design automation (EDA) vendors. As a designer of vehicular electronics systems, you must show that the EDA tools you use in your development flow meet the requirements of ISO 26262. Qualifying your EDA tools for use in the development of functionally safe chips can be a big effort that consumes precious resources, adds cost, and delays your schedule. Agnisys eliminates all that worry because we qualify our own tools as suitable for ISO 26262 design. Our entire IDesignSpec Suite and development flow is certified by the internationally known testing and inspection organization TÜV SÜD as having achieved the stringent tool qualification criteria defined by ISO 26262 as well as the related underlying standard IEC 61508. You can have high confidence in this certification, the result of a long and arduous process. TÜV SÜD conducted a detailed investigation of Agnisys tools, team, and development processes. They evaluated our tools and audited our product verification and validation flow, quality assurance (QA) procedures, configuration and release management, and user support procedures. Their endorsement means that you don’t have to worry about ISO 26262 tool compliance.

ConclusionWith our IDesignSpec Tool Qualification Kit (TQK), you can meet the requirements of both standards and satisfy the compliance demands of your customers. You need take no additional steps at all to qualify or certify our solutions when used in your development flow. A safety-critical IC is challenging for many reasons, but it’s vitally important to get it right. The electronics industry has many years of experience to draw on, and standards such as ISO 26262 are critical in establishing key requirements and best practices to satisfy them. With Agnisys as your executable specification automation solution partner, you can design automotive chips with automatically inserted safety mechanisms and qualify your development process with no effort needed to certify our solution. Tags: IDesignSpec Tool, ISO 26262, RTL designs Categories: Register Automation Solution, Semiconductor Expert |

|

|

|||||

|

|

|||||

|

|||||